PEEK’s high purity and ability to tolerate high burst pressures also make it an excellent choice for pharmaceutical, analytical, and biomedical applications to insure analyte fluids remain contaminant free. PEEK can withstand exposure to a wide range of acids, bases, and solvents.

PEEK Drawn Fiber is also an alternative for catheter braiding reinforcement where metal is not suitable.Ĭritical Fluid Transfer – The chemical resistance, mechanical integrity, and high maximum temperature of PEEK make it ideal for critical fluid transfer where heat is a prime concern. This monofilament is a perfect braiding material for wire and cable sheathing and performs well in extreme temperatures up to 500 ☏ (260 ☌). It is the end user’s responsibility to fully evaluate and test the fitness of the product for their specific application.īraiding – Our PEEK Drawn Fiber monofilament boasts excellent abrasion and corrosion resistance, tensile strength, and tenacity. Actual properties may change due to processing method, resin grade, extruded dimensions, and other variables. Note: The information in the Zeus website, catalog, and other sources presents and discusses generally accepted properties for non-pigmented virgin polymer resins from which Zeus fabricates its line of extruded products. Learn more about our Value Added services and our other performance options. We can also apply post-extrusion forming for a variety of demanding applications including heat forming, tipping, tapering, flaring, and flanging. Our PEEK Glide™ products give engineers a new option for applications that require the performance of standard PEEK, but could benefit from enhanced lubricity.Īt Zeus, we can extrude PEEK and PEEK Glide™ into many forms such as multi-lumen, monofilament, and our ultra-thin walled Sub-Lite-Wall™ tubing. We also offer PEEK in a more lubricious version, PEEK Glide™. In a biomedical setting, PEEK can be subjected to sterilization procedures such as autoclaving and gamma irradiation.

In analytical applications, PEEK’s high burst pressure, purity, and chemical resistance assure that PEEK tubing will stand up to the pressures needed for critical laboratory work and not contaminate the results. PEEK is replacing many metal parts allowing innovative applications with flexibility while reducing costs and weight for systems. PEEK’s considerable advantages as a material science solution are generating breakthroughs in many markets. This rigid plastic is considered one of the highest performing materials of its kind. We also have developed our Thermally Stable PEEK coating for fiber optics with extremely low attenuation throughout a range of 250 Celsius degrees. Our research, engineering, and production teams have developed a diverse collection of PEEK products to fuel innovation for applications in medical, oil and gas, aerospace, automotive, and high-performance liquid chromatography (HPLC). PEEK’s strength is complemented by its lubricity and high purity for demanding applications.

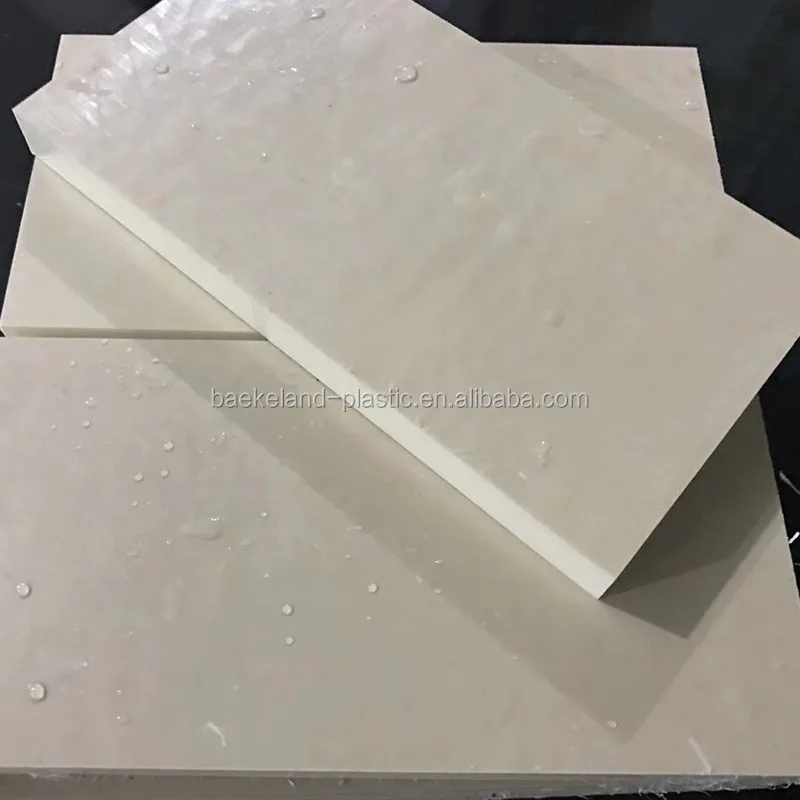

This material can be used as an alternative to other materials such as aluminum, steel, glass, and other polymers.

Polyether ether ketone, or PEEK, is a high-performance engineered polymer with excellent heat tolerance and one of the highest strength-to-weight ratios of any thermoplastic.

#Material peek natural free

Accelerate Your Prototyping – Order Free Samples

0 kommentar(er)

0 kommentar(er)